The main concept of WASTE2PLASTICS was initiated by the need to develop advanced bioprocesses for the management and valorization of industrial wastes/wastewaters and waste biomass generated from anthropogenic activities, into the concept of a circular economy approach. In this context, novel technologies will be developed that will valorize different types of wastes/wastewaters towards bio-based, biodegradable polymers i.e. polyhydroxyalkanoates (PHAs), which upon extraction from the microbial cells and purification will be formulated either to food packaging articles or to eco-friendly and fully biodegradable garbage bags.

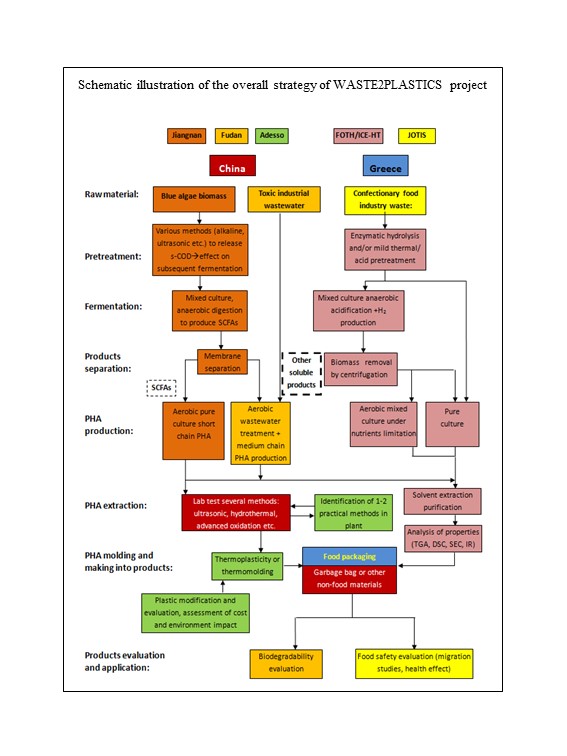

The overall strategy to be followed in the framework of WASTE2PLASTICS is illustrated in the figure bellow, where the research activities that will be performed by the Chinese and Greek partners individually and collaboratively are shown. As it concerns the individual tasks, FORTH/ICE-HT will focus, on the Greece side, on the utilization of various waste streams from JOTIS, focusing on milk products and syrups to produce PHAs either directly (one stage process) or after acidification (two stage process). Enzymatic hydrolysis and mild acid pretreatment will be applied for the fractionation of the feedstocks to carbon sources than be accumulated by PHAs producing bacteria, whereas physical fractionation will also be assessed. Acidification will be performed by acidogenic mixed consortia in mesophilic conditions aiming to the generation of different short chain fatty acids (SCFAs) mixtures which will be used as substrate to produce PHAs with optimal properties. Both pure microbial cultures (PMCs) and mixed microbial cultures (MMCs) will be used for the optimal PHAs production. MMCs will be acclimated and enriched under nutrient limitation under periodic feeding and/or dynamic conditions. The Chinese research partners, FDU and JNU will focus on the utilization of BAB and TIW. Initially, liquification of the BAB will be performed and subsequently a two-stage fermentation approach will be followed. Acidification of the liquefied BAB will be performed and subsequently a two-stage fermentation approach will be followed. Acidification of the liquefied BAB will then take place anaerobically, combined with hydrogen generation, and the produced SCFAs that will be generated will then be used by aerobic pure culture as substrates for PHAs production. Additionally, the residue wastewater generated from the acidification process will be further utilized for integrated PHAs production integrated into the main line. Biomass containing PHAs will be processed by ADESSO using novel technologies developed by ADESSO, JNU and FDU together. The aim is to develop cheap, safe, environmental friendly protocols for PHAs isolation and purification from microbial cultures. Lyophilized biomass and preliminarily extracted PHAs will be sent from Greece to China to be formulated into final products, whose properties will be tested there too. Analysis of the physicochemical properties of the stored and the extracted PHAs as well as the mechanical properties of PHAs films and final products will be performed throughout the course of the project by FORTH/ICE-HT. The health effect of the PHAs oligomers as well as the food safety and final products will also be assessed by FORTH/ICE-HT and JOTIS respectively. The biodegradability of PHAs particles and final products will also be studied by FDU and FORTH/ICE-HT.

Specific goals and objectives of WASTE2PLASTICS include:

- The valorization of different waste streams derived from confectionary industry, paper industry and environmental pollution via a) the development of integrated bioprocesses for the production of multiple types of PHAs from unconventional raw materials, b) the production of bio-based polymers to substitute for petroleum-derived materials, c) integration of bio-based polymer production in existing food companies and waste treatment facilities

- Evaluation of PHA properties as compared to conventional packaging by a) analyzing the mechanical, thermal and physicochemical properties of PHAs, b) assessing the life time and biodegradability based on the scenarios of continuous usage and subsequent disposal, c) assessing the health effect and food safety of PHAs

- Development of packaging for specific confectionary products and organic waste disposal by a) construction food packaging materials made of PHAs, b) formation of garbage bags for household green wastes, c) comply with environmental regulations, packaging law and consumer needs

Validation of sustainable development by a) the evaluation of process sustainability through process design, techno-economic evaluation and Life Cycle Assessment (e.g. reduction of CO2 emissions, waste generation and petroleum utilization), b)proposing solutions for the reduction of current cost for waste treatment